Search This Supplers Products:Digital Printers, Consumables, Accessories

How do Inkjet Printers Work?

time2022/06/08

- Since its introduction in the second half of the 1980s, inkjet printers have grown in popularity and performance, while prices have dropped significantly. In this article, you'll learn about the parts of an inkjet printer and how they work together to create an image.

No matter where you read this article, chances are you have a printer nearby. And most likely an inkjet printer. Since their introduction in the second half of the 1980s, inkjet printers have grown in popularity and performance, while prices have dropped significantly.

In this article, you'll learn about the parts of an inkjet printer and how they work together to create an image.

Influence and non-influence

There are several major printer technologies available. These techniques can be divided into two broad categories, each of which has several types:

Influences

These printers have a mechanism that touches the paper to create the image. There are two main impact techniques:

Dot matrix printers use a series of small needles to strike an ink-coated ribbon, causing the ink to transfer to the paper at the point of impact.

Character printers are basically computer typewriters. They have a ball or a series of bars with actual characters (letters and numbers) embossed on the surface. The appropriate characters are struck on the ribbon, transferring the image of the characters to the paper. Character printers are fast and crisp for basic text, but very limited for other uses.

Non-influence

These printers create images without touching the paper. Inkjet printers belong to this group, which includes:

Laser printers use dry ink (toner), static electricity, and heat to place and bond the ink to the paper.

Solid ink printers contain sticks of waxy ink that melt and coat the paper. The ink then hardens in place.

Dye-sublimation printers have a long roll of clear film that resembles red, blue, yellow, and gray cellophane, which is attached end to end. Embedded in this film are solid dyes corresponding to the four basic colors used in printing: cyan, magenta, yellow and black (CMYK). The printhead uses heating elements that vary in temperature, depending on the amount of specific color that needs to be applied. The dye evaporates and penetrates the glossy surface of the paper before returning to its solid form. The printer takes one full scan of each basic color of paper, gradually building up the image.

Thermal wax printers are a hybrid of dye sublimation and solid ink technologies. They use ribbons with alternating CMYK ribbons. The ribbon passes in front of the printhead, which has a series of tiny heated pins. The pins make the wax melt and stick to the paper, where it hardens.

Thermal automatic color printers have color in the paper, not in the printer. The paper has three layers (cyan, magenta, and yellow), each activated by applying a specific amount of heat. The printhead has a heating element that can vary in temperature. The print head passes over the paper 3 times to provide the proper temperature for each color layer as needed.

Of all these incredible technologies, inkjet printers are by far the most popular. So, let's take a closer look at what's inside an inkjet printer.

Inside an inkjet printer

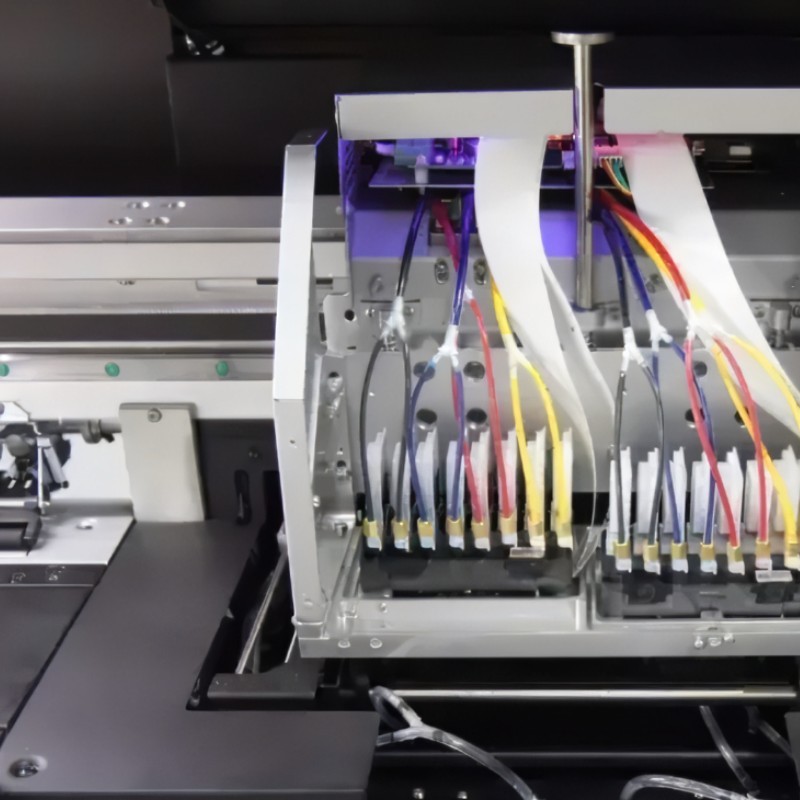

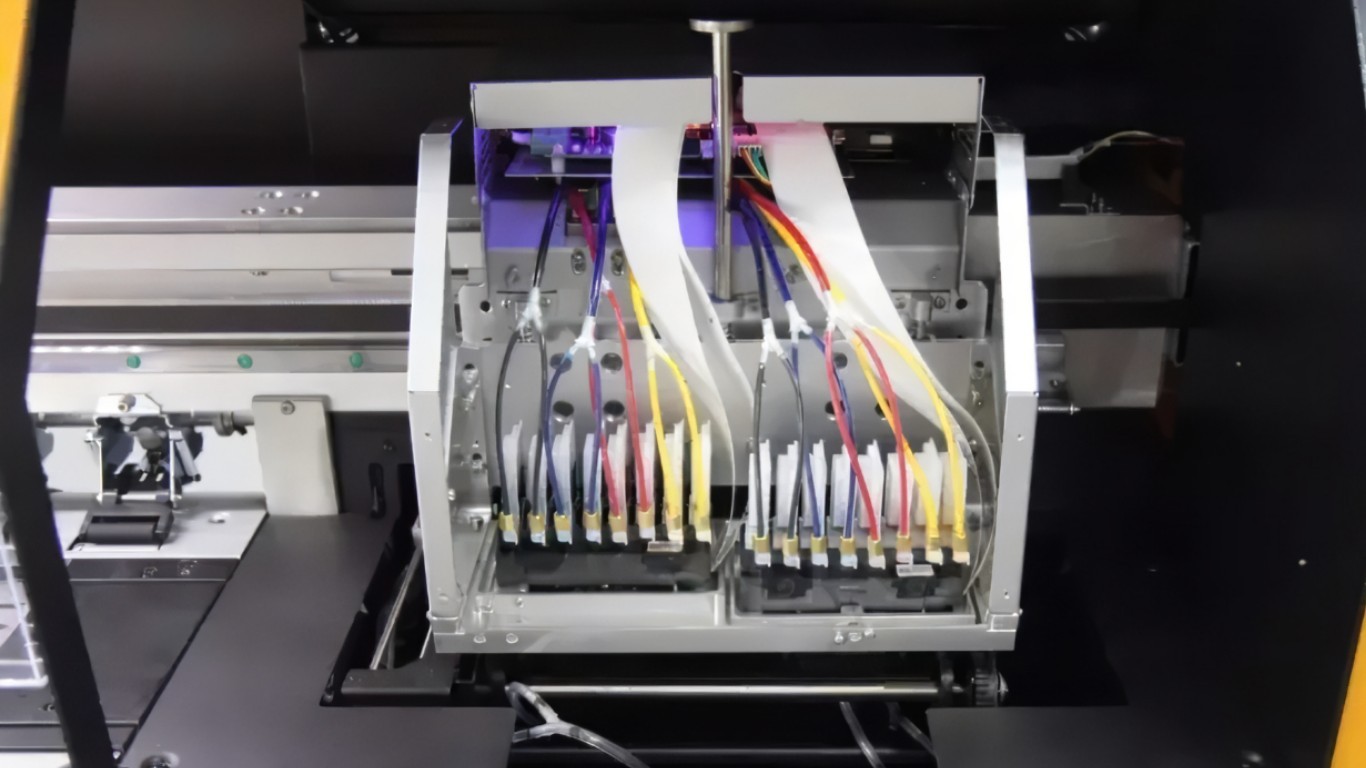

The printhead assembly includes:

Printhead - The heart of an inkjet printer, the printhead contains a series of nozzles that eject ink droplets.

Ink cartridges - Depending on the make and model of the printer, cartridges come in various combinations, such as separate black and color cartridges, color and black in a single cartridge, or even cartridges for each ink color. The cartridges of some inkjet printers include the printhead itself.

Print head stepper motor - The stepper motor moves the printhead assembly (printhead and ink cartridge) back and forth across the paper. Some printers have another stepper motor to park the printhead assembly when the printer is not in use. Parking means limiting unintended movement of the printhead assembly, such as the parking brake on a car.

Belt - The belt is used to connect the printhead assembly to the stepper motor.

Stabilizer bar - The printhead assembly uses a stabilizer bar to ensure precise and controlled movement.

The paper feed kit includes:

Paper tray/feeder - Most inkjet printers have a paper tray into which you can load paper. Some printers replace the standard tray of the feeder. The paper feeder usually opens quickly at an angle on the back of the printer so you can put paper in it. Paper feeders typically don't hold as much paper as traditional paper trays.

Rollers - A set of rollers that pulls the paper in from the paper tray or feeder and advances the paper when the printhead assembly is ready for another print.

Paper feed stepper motor - This stepper motor powers the rollers to ensure that the paper is moved in the precise increments needed to print a continuous image.

Power supply - While early printers often had an external transformer, most printers sold today use a standard power supply integrated into the printer itself.

Control circuits - Printers have small but complex circuits built into them that control all mechanical aspects of operation, as well as decode information sent from the computer to the printer.

Interface ports - Many printers still use parallel ports, but most newer printers use USB ports. Some printers connect using serial ports or Small Computer System Interface (SCSI) ports.

Inkjet printers are capable of printing on a variety of media. Commercial inkjet printers sometimes spray directly onto items like beer bottle labels. For consumer use, there are many specialty papers, from adhesive-backed labels or stickers to business cards and brochures. You can even get an iron-on transfer that lets you create an image and put it on a t-shirt! To be sure, inkjet printers definitely offer an easy and affordable way to unleash your creativity. If you want to buy an inkjet printer, please contact us.

Fullcolor is a professional custom inkjet printer and ink manufacturer. Products include: dye based inks, pigment inks, sublimation inks, environmentally friendly solvent inks, film inks, DTF printer inks, ink cartridges, inkjet printers, PVC/ID cards, card printers, label printers; sublimation/digital printing equipment, and consumables; Customized solutions are also provided to customers.