Search This Supplers Products:Digital Printers, Consumables, Accessories

DTF Printing: A Game-Changing Technology for the T-Shirt Business

time2023/03/31

- I'm sure you've heard of DTF printing before, but may not be familiar with how it works. Below we will introduce the relevant information on DTF printing to help you make a better choice.

I'm sure you've heard of DTF printing before, but may not be familiar with how it works. Or you may be confusing it with DTG printing.

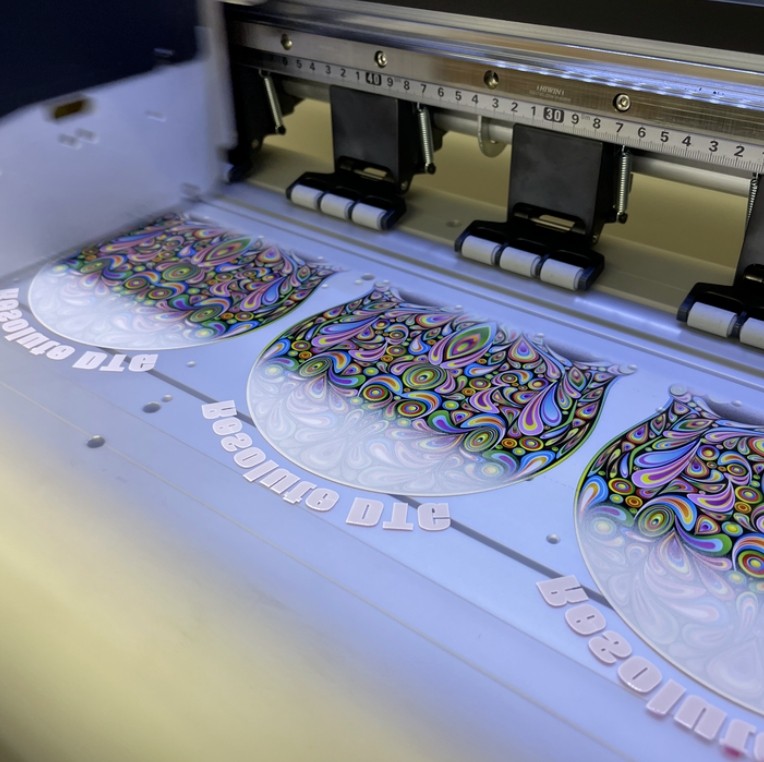

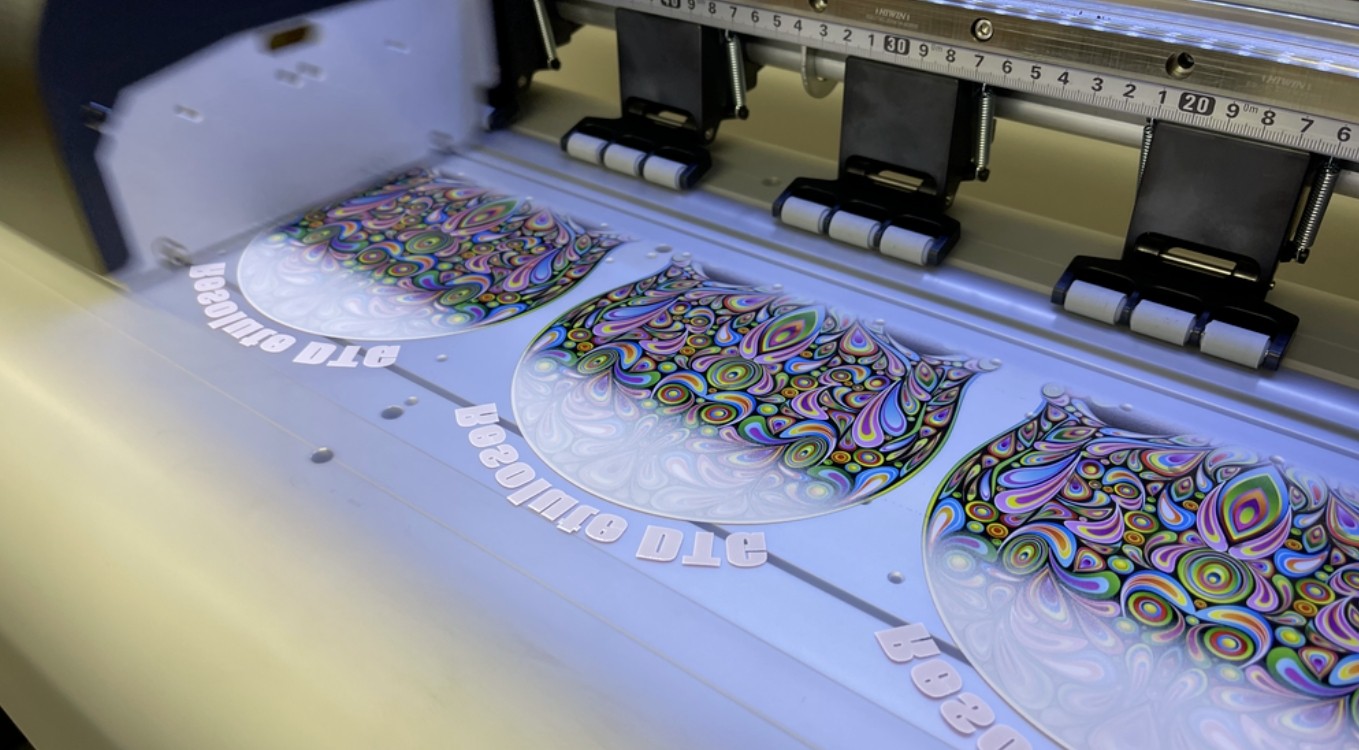

DTF stands for Direct to Film. This technique involves printing your design directly onto film, which is then transferred onto t-shirts made of cotton, polyester, or a blend thereof, regardless of their color, as it can use white ink.

Although it seems that DTF printing is a variation of transfer printing, it needs to be equipped with DTF ink specially designed for DTF printing and a DTF inkjet printer.

How to Print DTF Transfer?

A great advantage of this technique is that layers of white ink are printed at the same time as layers of colored ink. This feature makes it a very simple alternative to other methods such as white toner.

If you use DTF, you should know that the valid formats for print designs are: eps, ps, pdf, bmp, tif, jpg, png, and psd.

What Do I Need to Print a DTF Transfer?

Now that you understand DTF printing and what you can achieve with it, you may be wondering what equipment you need and how much of an investment it will be for your business.

What Do You Need?

Let's start by listing the equipment and machinery you'll need:

DTF Printers: Most of these printers are basic 6-color ink cartridge printers. This series of printers was chosen because these printers use 6 colors. This facilitates operation because CMYK DTF ink can go into standard CMYK ink tanks, while the printer's LC and LM ink tanks can be filled with white DTF ink. Also, the rollers used to slide the pages have been removed to prevent the "liner" from appearing on the white layer printed on the DTF film.

Special Inks for DTF Printing: These very flexible inkjet inks prevent the print from cracking when the garment is stretched after printing.

DTF Film: It is the surface on which you print your designs.

DTF Hot Melt Powder: It acts as a binder between the ink and the cotton fibers.

RIP Software: Necessary to print the CMYK and white layers correctly because, as mentioned earlier, the printer has been modified to print in the correct order by itself.

Heat Press: We recommend using a heat press with a vertically falling upper platen to make the curing process of the DTF film easier.

How Much Does DTF Equipment Cost?

Let's now look at the investment required to integrate DTF printing into your t-shirt personalization business. In fact, this is a great advantage of this personalization technique, as you can buy yourself a complete kit (printer + supplies) ready to install in your Shop and pay back your investment immediately.

In addition to a DTF printer and its consumables, you'll need a heat press or oven to cure the ink printed on the film.

When curing the ink, the heated platen must be at the same height over the entire printing surface. Therefore, we recommend using presses with the upper platen falling vertically so that its height can be adjusted.

Is DTF Printing What You're Looking For?

DTF printing is ideal for anyone looking to personalize t-shirts or any other textile product (cushion covers, masks, bags, sweatshirts, etc.) into their cotton or polyester business (and blends in any color) at a low-cost investment.

If you are already familiar with dye-sublimation printing, DTF is the perfect complementary technology to improve performance and make your business more profitable.

What do you think of this new personalization technology? Do you want to incorporate it into your personalization business? If you have any other questions about DTF printing, please feel free to contact us. FCOLOR is a professional custom inkjet printer and ink manufacturer with 12 years experience. Our products include DTF printers, inkjet printers, PVC/ID cards, card printers, label printers; dye sublimation/digital printing equipment and consumables, dye inks, pigment inks, sublimation inks, film inks, DTF printer inks, and ink cartridges. We also provide customized solutions for our customers.

This product has strong compatibility, good printing effect, high-quality materials, high transfer rate

DTF ink prints with bright colors, high degree of pattern printing, clear and smooth without clogging

1. Product name : Mini oven

2. mini oven size : A4 A3 A3+ pet film

3. stock :YES

4. easy to handle

PU Powder,Good Health is the Best.