Search This Supplers Products:Digital Printers, Consumables, Accessories

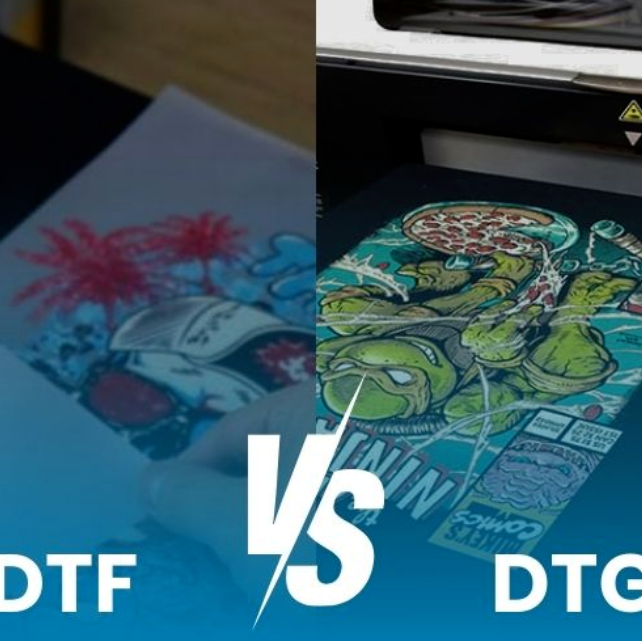

DTG vs. DTF Printing - Which Printing Method is Right for You?

time2024/10/15

- Thinking of printing apparel with your own designs? Consider DTG vs. DTF printing—each affects cost, production time, and quality. Learn which method best suits your merchandise needs.

Have you ever thought about printing some beautiful apparel and other merchandise with your own original designs? You might also want to think about the printing process! Two printing methods are often used in merchandise creation: DTG and DTF.

Each method has key differences and can impact cost, production time, and the look and quality of the final product. Let's take a look at how DTG and DTF printing work and help you decide which printing solution is best for you and your merchandise.

What is DTG Printing? How Does it Work?

DTG printing, or direct-to-garment printing, is a versatile technology that involves applying ink directly to the surface of a garment, such as a t-shirt or hoodie. DTG fabric printers work much like a home inkjet desktop printer applies ink to paper. DTG printing utilizes specialized printers equipped with advanced technology to transfer ink to the fabric, allowing for intricate designs and rich colors.

Direct-to-garment printing allows for high-quality, soft-touch printing that blends seamlessly with the fabric and is comfortable to wear. The DTG printing method is a popular on-demand printing method that prints one item at a time; DTG printing can be used on mixed fabrics (tri-blends) and polyester, works great on cotton, and can even produce beautiful reproductions of photographs on fabric.

How Does DTF Printing Work?

Learn more DTF, or direct-to-film printing, is a method whereby an image is printed with ink onto a special film, which is then transferred to the garment. DTF is a newer printing technology that is a combination of DTG printing and screen printing, making it a versatile method. DTF printing works by printing an image onto a special film using a specific ink formulation, which is then thermally transferred to the garment.

This produces a bright, resilient, and durable print with an extra dimension, so DTF printing works well on a wide range of fabrics and design styles, including polyester, nylon, cotton, and blends; it works best on thicker, heavier fabrics that can better support film-based thermal transfer printing.

Key Differences Between DTG Printer and DTF Printer

Cost

Understanding the financial aspects of direct-to-garment and direct-to-film printing methods will help you make a better decision about which printing method to choose. Basically, the initial cost of direct-to-garment printing may be slightly higher due to the specialized equipment and ink requirements, while direct-to-film printing is widely available and uses less ink, making it a more affordable option for creators looking to get the most bang for their buck.

Production Time

The choice between DTG and DTF printing can significantly impact production timelines. DTG printing takes the lead with its fast printing process for smaller batch orders that require a quick turnaround. But DTF printing can be more time-efficient and suitable for larger batch orders, allowing creators to handle large orders without compromising quality.

Quality

The choice between direct-to-garment and direct-to-film printing has a direct impact on the final product. DTG printing is ideal for designs with rich details and deep colors and offers a softer finish that absorbs into the fabric and looks like it's part of the garment. DTF prints sit on top of the fabric like a film or thin decal with a smooth texture, making them ideal for bright, vibrant colors and heavy graphics.

DTG printing provides good results for all types of designs, with DTF printing being better suited for smaller designs where the print itself doesn't feel too thick or stiff when worn.

Color Vibrance

Color vibrance is what makes printed garments look rich and high quality. DTG printing stands out for its ability to render vivid, dynamic, blended colors that enhance the visual appeal of merchandise; the only thing it doesn't do as well is with transparent designs.

DTF printing uses a unique printing process and “applique” look to provide a different but equally appealing color experience, ensuring that creators can achieve the desired color on a variety of fabrics with either option. Both DTF and DTG printing use the CMYK (cyan, magenta, yellow, and black) ink color model to achieve the same wide range of colors.

Print Durability

The durability of prints on garments is an important factor for creators who want to provide their audience with durable merchandise. Prints directly on garments, especially on cotton, have good durability with proper washing and drying, although colors will slowly fade over time. Direct-to-film printing exhibits good durability on a variety of fabrics, but without proper fabric care, printed images, especially larger images, will eventually crack. Both DTF and DTG printing produce high-quality prints that look great and can be worn and enjoyed over a reasonable lifespan.

Order Quantity

The size of your project is also an important factor in deciding whether to choose DTG or DTF printing. If your focus is on small runs or on-demand print orders, such as limited editions or special series, DTG printing's efficiency, precision, and the simpler setup of DTG printer equipment on the production side make it an ideal choice. If you're catering to a wider audience, DTF's ability to handle larger batches can streamline your production process.

Sustainability

With sustainability being a growing concern, it makes sense for creators to be mindful of the environmental impact of their choices. DTG printing works similarly to large-scale inkjet printers, using water-based inks as the primary ingredient, which is considered more environmentally friendly and reduces the risk of harmful chemicals entering the environment.

DTF transfers do present some environmental concerns, as the thermal transfer films used for DTF may contain chemicals/materials that are harmful to the environment; so you may want to check that the company you are using can confirm that they properly and safely dispose of these leftover materials.

Which Printing Method is Right for You?

Choosing between DTG printing and DTF printing depends on several factors. Consider the fabric you are printing on, your color preferences, the complexity of your design, and the scale of your project.

If your focus is on rich, vibrant colors, intricate and detailed patterns, and soft prints that blend better with fabrics, DTG printing may be your first choice. If you want high-volume, bright, small-scale patterns at a low cost, then DTF may be a good choice for you.

Either way, be sure to analyze your needs and let them guide you to find a method that meets your product goals.

Achieve Your Printing Goals and More with FCOLOR Printers

FCOLOR is a professional custom inkjet printer and consumables manufacturer. Its wide range of products includes DTF printers and inks, dye inks, pigment inks, sublimation inks, eco-solvent inks, film inks, cartridges, and inkjet printers. In addition, we also provide PVC/ID cards, card printers, label printers, and a range of sublimation and digital printing equipment and consumables. FCOLOR is committed to providing customized solutions based on the specific needs of our customers, ensuring that we meet the highest quality and performance standards in the printing industry.

With 30 years of experience in printer inks, FCOLOR has developed products that can achieve printing results that are almost the same as the original inks, with an accuracy of up to 98%. With rich expertise, we are able to provide high-quality, reliable printing solutions to meet a variety of application needs. Whether for professional, commercial or personal use, FCOLOR's inks and printing equipment are designed to produce bright, durable prints comparable to the original products. Our commitment to innovation and customer satisfaction has consolidated their leadership in the inkjet printing industry. If you are looking for a reliable manufacturer of inkjet printers and consumables, welcome to contact us.

DTF printer High precision nozzle printing clearer image 60cm roll to roll direct to film printer

MAX Print Size A3+ (13x19'' )

Work with PET Film Transfer ink + Hot Melt Powder + PET Film Transfer

13 inch 8 Colors DTG Printer Direct to Garment Printer Dual I3200M Printheads T-Shirt Printing Machine for Hoodies Pants

DTF ink prints with bright colors, high degree of pattern printing, clear and smooth without clogging