Search This Supplers Products:Digital Printers, Consumables, Accessories

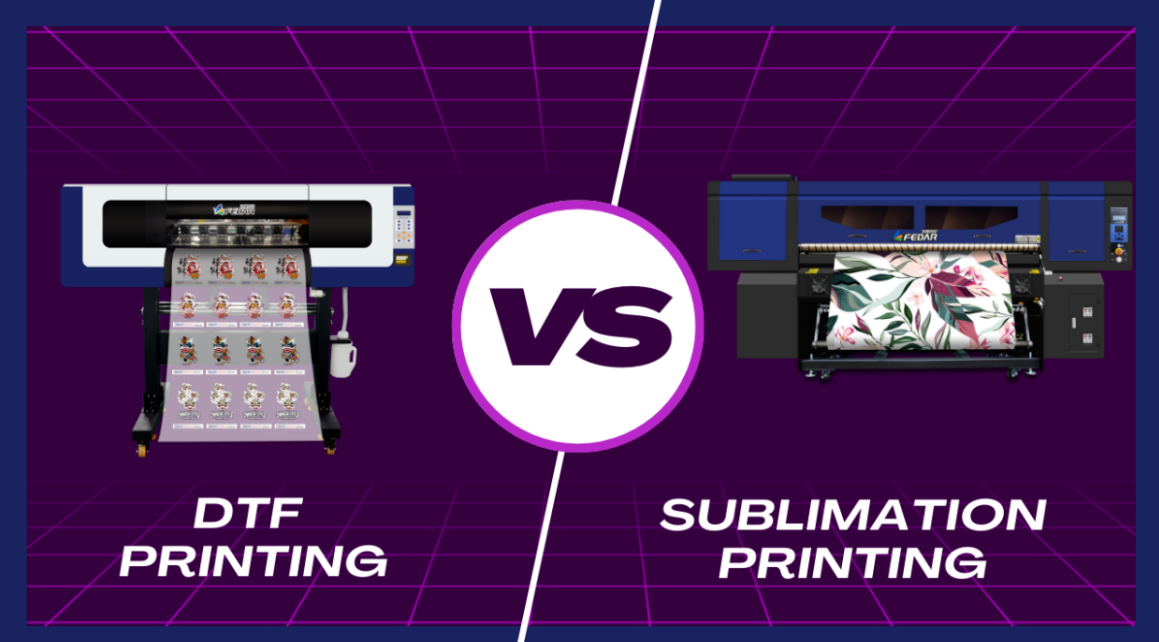

DTF vs. Dye Sublimation - Which Printing Option Is Better?

time2024/10/30

- DTF and sublimation offer vivid, detailed prints and fall under thermal transfer methods. Each suits different needs—FCOLOR provides a detailed comparison to help you choose the right one.

If you are looking for a printing technology that can produce impressive results, then DTF and Dye Sublimation would be the top two contenders. Both printing methods can provide high-quality prints with excellent details and vibrant colors. In addition, they are also both categorized under the thermal transfer printing section. However, they have some significant differences that make each suitable for different purposes.

To better understand the differences and how to adapt each printing method, FCOLOR will guide you through a detailed comparison of the two printing technologies.

What is DTF Printing?

Direct film printing is one of the latest inventions in the printing industry. The introduction of DTF has helped to eliminate many limitations in printing. For example, DTF can print on a variety of materials, from synthetic fibers to natural fiber fabrics. It can also handle complex designs with intricate details and vibrant colors.

Technically speaking, DTF can be considered a form of thermal transfer printing. It does not require direct printing onto the material. Instead, the design is printed onto a PET film and then transferred to the substrate using a heat press.

The outstanding capabilities of DTF stem from subtle technical improvements here and there.

- Pigment-based inks: DTF uses specialized pigment-based inks that deliver high color vibrancy and durability. These inks adhere well to film and subsequently fabric, ensuring long-lasting, richly colored prints.

- DTF printers: DTF uses specialized printers that enable high-resolution printing with fine details, which is often a challenge with other transfer methods.

- PET film: DTF uses high-quality PET (polyethylene terephthalate) film. This transfer film is heat-resistant and has a smooth surface, ensuring consistent printing without wrapping or warping, and excellent ink deposition. PET film, in particular, is compatible with a wide range of fabrics, including cotton, polyester, blends, and synthetics.

- Bonding powder: DTF uses heat-activated bonding powder as a bonding agent. This powder is applied to the printed film. During the heat pressing process, it melts at high temperatures to form a strong bond between the ink and the fabric. This makes the print more durable and resistant to washing and stretching.

What is Sublimation Printing?

Similar to other heat transfer technologies, sublimation uses the same mechanism to create prints: the print is transferred from the transfer paper to the substrate and bonds to the material under high temperature and pressure.

Although the process is the same, sublimation printing has a secret that allows for some impressive print effects. This special dye-based ink can be directly transformed from a solid state to a gas state without going through a liquid state, which is why it is called sublimation. This ink is the special factor that creates the magic of sublimation: it allows the ink to penetrate the fibers of the substance and become part of the material.

Similarities between DTF and Sublimation

Both DTF and sublimation rely on heat and pressure to transfer the printed image to the substrate. Therefore, whether you use sublimation or DTF, you will need a heat press.

Compared to other printing methods, DTF and sublimation printing have one common advantage: both can provide high-quality printing results with high precision. Both printing methods can bring the vitality and complexity of the design to life, creating fascinating and impressive prints on fabrics.

Another advantage of both printing technologies is that they can accurately portray a wide range of colors. It is perfect for showcasing photographic designs and special graphic effects such as gradients. This opens up endless possibilities for printing.

DTF and sublimation printing are also two popular printing options for custom and personalized orders. Since neither requires complicated setup, it is easy to switch designs. You can also use both options in the print-on-demand business, which is also popular, especially sublimation printing.

Differences between DTF and Sublimation

Materials

DTF has an advantage over sublimation when it comes to versatility. This advanced printing technology is compatible with a wide range of materials, including cotton, polyester, nylon, blends, etc. And the printing quality remains consistent across different materials.

Sublimation printing, on the other hand, is only suitable for polyester or polyester-coated fabrics. If you use sublimation printing on natural fiber fabrics such as cotton, the print will not penetrate into the fibers, causing it to fall off or peel off easily.

In addition, sublimation ink can only be printed on white or light-colored materials. But with DTF, the prints will shine no matter what material they are printed on.

If you value versatility and like to work with all types of materials, then DTF is a better choice for you.

Durability

In terms of durability, sublimation printing can outperform almost all printing methods to date, including DTF. The working mechanism of converting the ink into gaseous form and then back into solid form allows the ink to penetrate deeply into the fibers.

Instead of sitting on the surface, sublimation dyes penetrate the fabric and become one with the material. This deep fusion creates incredibly resilient prints that will not peel or fade no matter how many times they are washed.

Texture and Feel

As mentioned above, sublimation prints blend seamlessly into the material. You can feel the original soft texture of the fabric without feeling the print. On the other hand, DTF prints have a slightly raised texture that makes the material thicker.

Full Printing Compatibility

Since the dye is embedded into the fibers, the fabric retains its original texture and flexibility. This is especially important for full-width printing, as it ensures that the garment remains comfortable and retains its natural feel. In addition, sublimation printers can process large rolls of fabric, allowing for continuous, uninterrupted printing. This makes it possible to create patterns that cover the entire surface of a garment, such as T-shirts, leggings, and even large items such as sheets and curtains.

In contrast, DTF prints often have a slightly noticeable texture on the fabric. The bonding layer may also affect the flexibility of the fabric, especially on larger surfaces. Therefore, it is not suitable for full-coverage printing. Unlike sublimation, DTF printing usually uses PET film to transfer the pattern. These films come in standard sizes, which may limit the size of the pattern.

Which One to Choose?

Both sublimation and DTF are suitable for the on-demand printing business because they are flexible for customization and personalization and are not subject to minimum quantity restrictions.

When to Choose DTF?

DTF is a great choice for small and medium-sized businesses. It has versatility and allows you to experience different types of materials and products, allowing you to get involved in many areas of the market. In addition, the initial investment cost is manageable, which is suitable for small and medium-sized businesses. The running cost of this printing method is also low, so you don't have to invest a lot.

When to Choose Sublimation?

Sublimation printing is larger in scale, occupies more space on the printing press, and has a higher investment. All of this makes sublimation printing only suitable for established businesses and not for smaller, newer businesses.

In addition, sublimation printing works well on synthetic fibers such as polyester and nylon, which are often used in sportswear. It is a wise choice to choose sublimation printing for printing sportswear.

Conclusion

Both DTF and sublimation printing offer unique advantages and are valuable tools for meeting different printing needs. Whether you are just starting out or looking to expand your printing capabilities, understanding these methods can help you make the best choice for your business. Don't be afraid to explore both technologies and find the one that best suits your needs. With the right approach, you can produce stunning, high-quality prints that will impress your customers and set your business apart. FCOLOR can provide high-quality sublimation and DTF printers and consumables. If you are looking for a reliable printer and consumables manufacturer, welcome to contact us.

As a professional custom inkjet printer and ink manufacturer FCOLOR offers a range of printers and consumables. Our extensive product line includes dye inks, pigment inks, sublimation inks, eco-solvent inks, film inks, and DTF printer inks. In addition, we also offer ink cartridges, inkjet printers, PVC/ID cards, card printers, and label printers. For those involved in dye sublimation or digital printing, we provide the equipment and consumables needed to achieve high-quality results. Whether you need a custom ink formulation or a custom printing system, our team is committed to providing innovative and efficient solutions to enhance your printing capabilities. Our commitment to quality and customer satisfaction makes us a trusted partner in the printing industry.

DTF printer High precision nozzle printing clearer image 60cm roll to roll direct to film printer

FCOLOR L8058 3D sublimation printer with 3D Sublimation Vacuum heat transfer machine for phone cases

L8058 3D sublimation heat transfer printing machine for clothing printing

Perfect printing performance, Color vivid, Wide color gamut, closer to the kind;

This product has strong compatibility, good printing effect, high-quality materials, high transfer rate