Search This Supplers Products:Digital Printers, Consumables, Accessories

dual head i3200 dtf printer

- group name

- dtf printer

- Min Order

- 1 piece

- brand name

- Fcolor

- model

- DTF600B

- Nearest port for product export

- Guangzhou, Shenzhen, Yiwu

- Delivery clauses under the trade mode

- FOB

- Acceptable payment methods

- T/T, D/P D/A, MoneyGram, PayPal, Westem Union, Cash

- update time

- Tue, 03 Feb 2026 06:17:57 GMT

Paramtents

Printhead Dual head/3200

Supports Ink Output K-C-M-Y-W

Max Printing Size 600mm

Package Size 1800x750x640 mm

Weight 130kg

Power Require AC 220V 0.5kw (w/o Heater)

Packging & Delivery

-

Min Order1 piece

Briefing

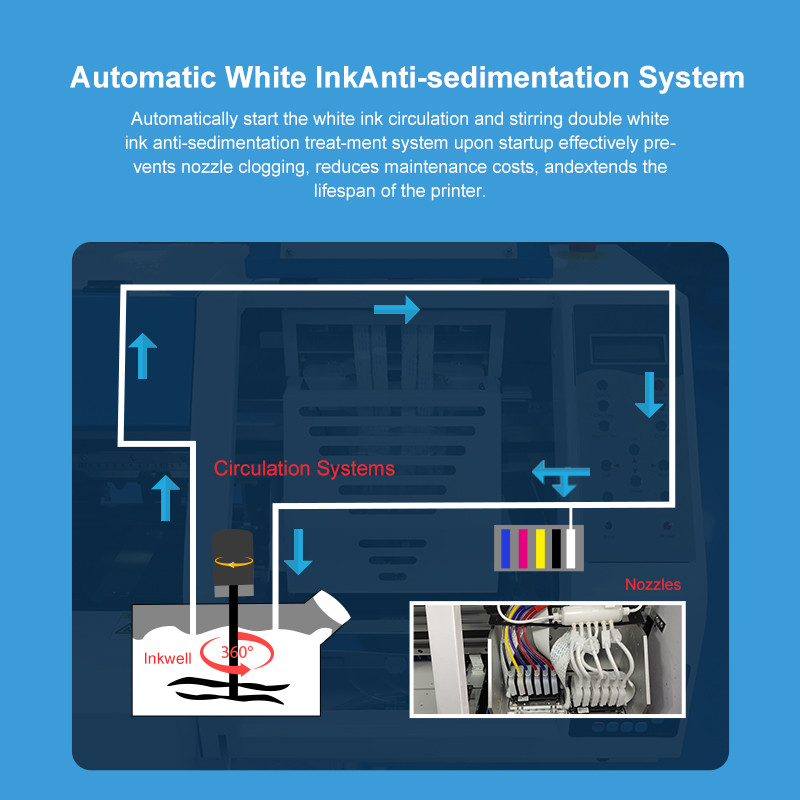

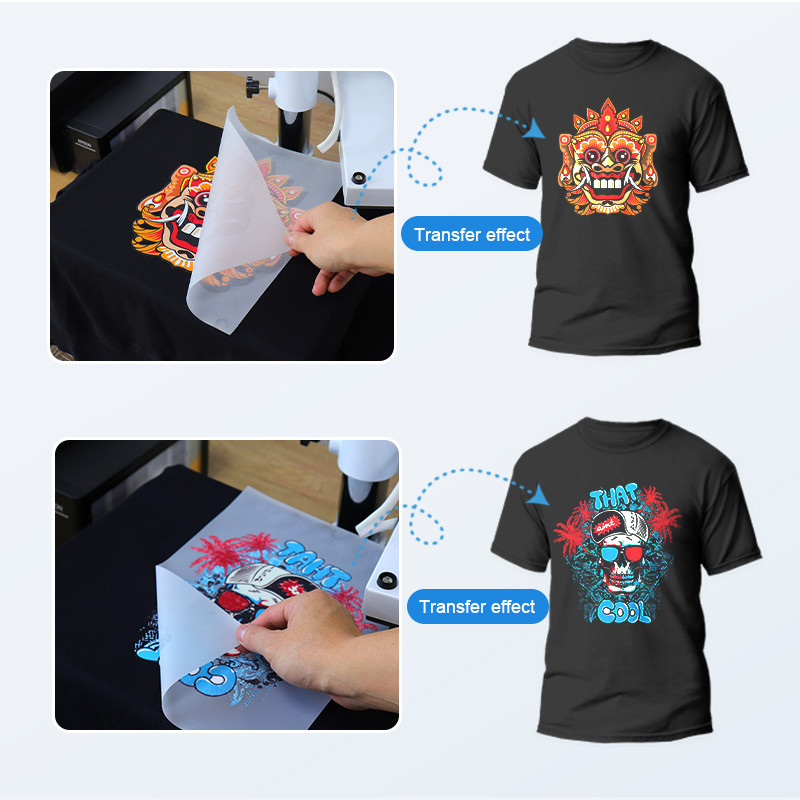

Improved DTF inkjet digital printing printing, more complete features, more secure digital printer.

Detailed